Complex supplies of industrial automation

We can help you prepare and implement investment and modernization projects. We provide consultancy regarding the preparation of a suitable technical and economical solution, stages and schedule of the project. Our experienced engineers can help you minimize the risks related to investments into new technology as well as with modernization of the current technology. We follow the quality engineering methods: the method of Good Engineering Practice (GEP).

Analysis and specification

We can analyse your production and offer the best solution from both technical and economic points of view. On the basis of the analysis, a description of the problem is drawn up and work is started.

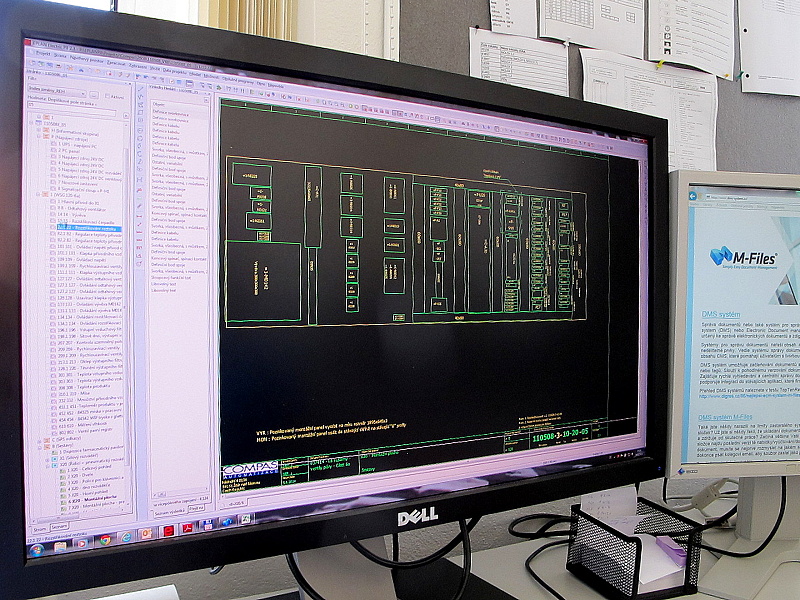

Projection

We respect the specific requirements of the particular industry. The project documents may be prepared in accordance with your requirements or on the basis of executed analyses of automation of the technological equipment or machinery. Projects are prepared in compliance with the valid EN standards. We use CAD systems ePLAN and AutoCAD for project preparation. The finished documents are saved in the DMS system (M-files).

Automation projects are prepared as complete, including:

- Power supply part

- Control and information system part

- Instrumentation part

- Measurement and regulation

Complete project documentation is a matter of course.

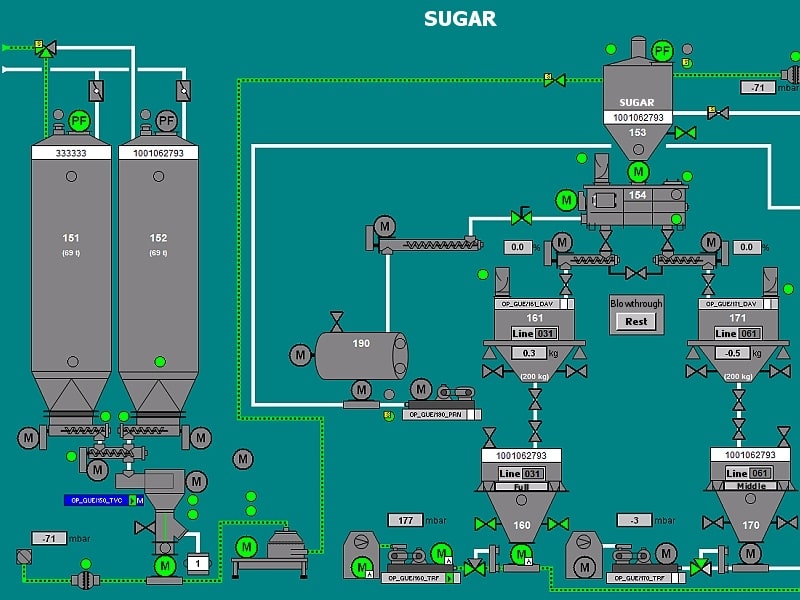

Control systems

We develop control system applications for various industries. We deploy SIEMENS control systems, drives and other elements of the TIA components. For discrete production, we use Simatic S7 PLC; for control over larger technological processes we apply process control system Simatic PCS7. As HMI, we use operating panels and HMI WinCC or InTouch visualizations.

As the second platform we propose applications of Beckhoff control systems becoming more and more popular.

We apply control systems Siemens and Beckhoff

- Simatic S7 1500, 1200, 400, 300, 200 and Logo

- Process control system Simatic PCS7

- Simotion for control over technology with drives

- SIEMENS operator panels OP, TP, KP of the Comfort and Basic series

- HMI WinCC, TIA portal HMI

- SCADA InTouch and WW System Platform

- Beckhoff control systems with application SW developed with TwinCAT2 and TwinCAT3

Services

- Consultancy and technical assistance for clients, we advise perspective solutions with regard to extendibility and maintenance

- Design of suitable system architecture and in industrial networks and I/O

- Design of the automation with drives

- Configuration of DCS systems, redundant systems

- Design of “Fail Safe” systems (safety according to IEC 61508)

- Proposal of PLC and HMI visualization (SCADA, panels)

- Application of flexible recipe systems

- Control over batch processes according to ISA S88 (Batch)

Application Software Development

- Functional specifications, design specifications

- Control SW development

- FAT, SAT tests

- Individual and complex tests, trial operation

- Training operators and users

- Long-term support, service and spare parts arrangement

- SW Development Department for Process Control Systems

- Siemens Step7 – Configuration of HW (PLC, I/O, Networks …)

- Siemens TIA portal – HW Configuration

- Programing in the Siemens TIA portal

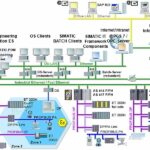

- Process Control System Simatic PCS7 Architecture

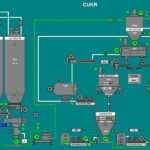

- HMI Visualization – Siemens WinCC

- HMI WinCC – the Alarms Management

- COMPAS Standard Faceplate library – the Motor

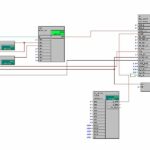

- Example of the Continuous Function Chart Control (CFC)

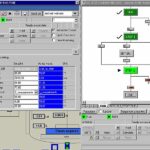

- Example of the Sequential Function Chart Control (SFC) Visualization

- Operator Station with two Heads – Simatic PCS7 + Simatic Batch

- Control of the Production Steps by the Simatic Batch CC

Visualization of HMI and own library

Special Offer – Faceplate Library for WinCC

Our team of experts has designed the FACEPLATE object library for HMI WinCC that increase the capacity and productivity of HMI programmers as well as control applications. FACEPLATEs improve the quality of HMI and reduce the cost of the application. FACEPLATEs simplify and unify HMI interface by grouping the available control/status of elements for the equipment (sensor, valve…) and allow standardization and better quality of process control by the operator.

More information see at FACELATEs.

- SW Development Department for Process Control Systems

- Siemens Step7 – Configuration of HW (PLC, I/O, Networks …)

- Siemens TIA portal – HW Configuration

- Programing in the Siemens TIA portal

- Process Control System Simatic PCS7 Architecture

- HMI Visualization – Siemens WinCC

- HMI WinCC – the Alarms Management

- COMPAS Standard Faceplate library – the Motor

- Example of the Continuous Function Chart Control (CFC)

- Example of the Sequential Function Chart Control (SFC) Visualization

- Operator Station with two Heads – Simatic PCS7 + Simatic Batch

- Control of the Production Steps by the Simatic Batch CC

Measurement and control

We offer many years of control experience with both standard PID controllers and applications with predictive controllers. In order to regulate, there must be reliable measurement and therefore feedback. We can help you with the selection of high quality and functional measuring devices that we have tested over 30 years of existence.

Peripheries

- We design and supply sensors and actuators

- Cameras, control system peripherals for industrial networks (e.g. I/O from various manufacturers)

- Material marking systems, BC, RFID

- Systems for tracking of material movement, navigation of AGV trucks

- Computer vision systems for robot navigation or quality control

Drives

Application of Electrical Drives

We offer the solutions for all tasks related to the application of electrical drives in production mechanization and automation. We provide integrated services, starting with the design and ending with the delivery and service. Our specialists have experience with the application of electrical drives both for simple and complicated tasks. You can check some of our applications under Case Studies.

Regulated Electrical Drives

We mainly focus on the regulated drive series by SIEMENS. We provide integrated services: from the design to the delivery and service of the application with the electrical drives. Our specialists also have experience with large international projects where dozens of regulated drives were applied. Some of our applications are pilot in the industry, such as in the field of fast drive control by the Simotion/Sinamics systems. We can integrate drive control with the superior PLC SIEMENS control systems.

Activities in the Field of Electrical Drives

For electrical drives related tasks, we offer optimal parametrization of drives; for more demanding tasks (positioning, speed control), we develop SW for the drive control systems by SIEMENS.

We offer the following activity for applications:

- Elaboration of the task analysis, recommendation of a suitable drive and the method of control

- Designing all related components of the power part of the drive

- Designing communication between the drives and the control system

- Elaboration of the drive project

- Development of the application software implemented in the drives (regulative, synchronizing, algorithm…)

- Delivery of the individual designed components, including assembly and commissioning

- Installation and connection of the drive and all related components

- Check and basic tune-up of the drives (motor identification, current and speed controller)

- Parametrization and setting the control and technological values of the drive (torque limitation, ramps, temperature parameters, overload, communication…)

- Tests of the drive from a local workplace – response of the drive to the commands, application software tests

- Complete diagnostics and online monitoring of the behaviour of the drive, both locally and remotely

- Service for the regulated drives by SIEMENS

Suitable areas for the installation of regulated drives and references

- Rotary machines (pump, ventilators, conveyors, coiling/uncoiling machines etc.)

- On-the-fly material cutting (monitoring regulation, cut-to-length application for shears, saws, dividing machines for rolling mills)

- Lines with force, torque and speed regulation of drives in cascades, in the Master/Slave mode (extrusion lines – cable lines, rubber lines, extruders).

- Load-sharing regulation (work of several drives sharing one load)

- Positioning mechanisms using the “standalone” drive (manipulators, feeding mechanisms etc.)

- Positioning and speed synchronization of two and more drives (axes)

- Solutions for equipment automation by the SIEMENS Simotion drive control systems, such as for the electric screw press and glass-processing machine for making bottles.

Diagnostic systems

Diagnostic systems are used to detect errors in industrial processes, production lines and equipment. They are used to tune processes and equipment, as a window into production for monitoring and optimization. They are particularly indispensable in finding random errors in processes or mechanical equipment and production lines.

We supply world-leading software from IBA, which is used to monitor dozens of process signals, I/O control systems. At the same time, it can also take HMI and video recordings from up to 64 cameras. The measured data is continuously stored in measurement files.

Features of the IBA diagnostic system

- Synchronous recording of video images and measurement data

- Continuous and event-triggered recording

- Recording of HMI and camera images

- Capture from up to 64 cameras (analogue, IP, GigE or virtual) and online visualisation

- View and analyze signal trends and video sequences

- Live video display as a replacement for CCTV system

- Possible integration of third-party software for image analysis, supplementing the original camera footage with additional data and back-synchronous recording of the resulting image into an archive

- Integrated communication interface for data acquisition from PLCs of leading manufacturers (AB, ABB, B&R, BECKHOFF, SIEMENS, …)

- Convenient analysis tool IbaAnalyzer free of charge

- PLC signals (IbaPDA) + HMI recording (IbaCapture) + camera recording (IbaCapture)

- CTTV replacement (IbaCapture)

- Recording from HMI (IbaCapture) + recording from camera (IbaCapture) + recording from IbaVision (image analysis, measurement of the dimensions of the shaft, addition of data from PDA)