Faceplates enhance effectivity of programing and increase quality of HMI applications by grouping control and status elements for tags and process objects. With faceplates it is possible to make HMI operation standardized and more efficient.

WINCC FACEPLATE – FUNCIONAL DESCRIPTION

Faceplates consists of two parts, function blocks PLC STEP7 (FBs) and WinCC scripts (C, VB). The blocks put together the library developed by COMPAS automation (Czech republic).

Benefits of Faceplates for system integrators:

The Faceplate library simplyfies development of HMI application (saves time and costs)

The Faceplate library increases quality of the applications using validated SW components

The Faceplate library simplifies customers support by HMI standardization (easier work in engineering team)

Benefits of Faceplates for users:

The Faceplate library unifies HMI for operators of lines, technologies, plants

The sofisticated functions improves HMI operation

Diagnostic information detects failure of instruments and technological objects

With faceplates in-built access rights for operation of objects and technology you can easy define operation level for users

There are in-built data functions in faceplates e.g. counting of motohours etc.

Faceplate Library

The library consists of components:

- Digital imput with detection of failure

- Analog sensor with calibration

- PID regulator

- continuous

- with step control

- Phase – complex block for Batch control in accordance with ISA S88 (Batch) standard as well as for sequences in PLC programs

- Motors

- with digitral control

- wit frequence convertor

- Valves – with/without evaluation of actual position

- with digital control

- with analog control

Note

Besides above mentioned blocks the Faceplate library includes also blocks for user convenient operation:

Operator anouncement – configurable information to the operator with the acceptance

Block with conditions – serves for prezentation of statuses od objects

Comparaton block – serves e.g. for evaluation of failure situations

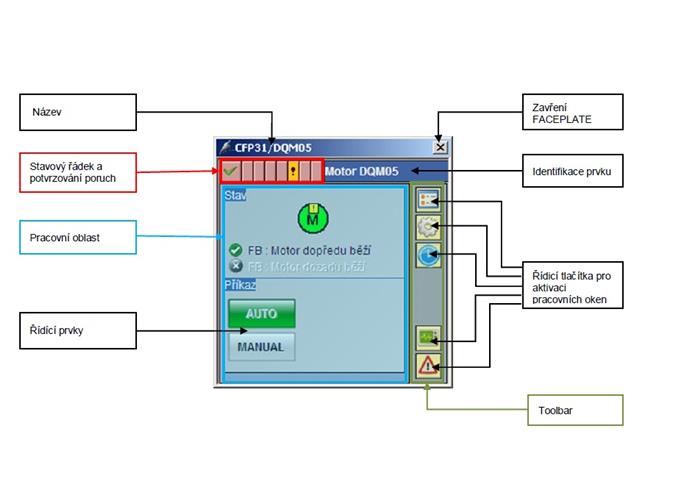

Faceplate structure

Example for a Motor Faceplate

- Basic mask consists of status and control functions

- Futher marks are available under folders:

-

- Alarms

- Trends

- Parameters

- Further masks for object specific functions (calibration, conditions, logical operations,…)

HOW AN OPERATOR USES WINCC HMI WITH FACEPLATES

a. There is the icon on the WinCC screen for object (e.g. valve)

![]()

Colour atributes serve for status information (working regime, alarm…)

b. Operator clicks by mouse to the icon and activates opening of the valve faceplate.

Note: It is possible to open more faceplates on the HMI screen

c. If operator needs more information than swith to other mask by toolbar function.

d. The operation ends by closing the Faceplate.

Faceplate Library Licence

In case of your interest or query please contact us by e-mail info@compas.cz.

- COMPAS WinCC library – analog imput faceplate

- COMPAS Faceplate knihovna – objekt ventil