Steckel/Plate Mill AHMSA, Moncolva, Mexico

Hot plate and strip steel mill automation

COMPAS delivery included control of the dividing sections in the hot rolling mill and finishing plant for steel plates.

The project included development and commissioning of control programs in the following devices:

- Disk cooling beds for plates

- Double side rotary trimming shears for plate cutting to the required width

- Dividing shears for cutting the basic plate into plates with commercial lengths

- Stacking final plates (Piler machine) and their delivery from the warehouse

- Media systems

- HMI

Automation Project

Control of the finishing plant of the plate rolling mill from the input to the cooling bed to the stacking and dispatch of plates.

The engineering delivery included:

- Control SW development

- Development of the HMI WinCC level

- Commissioning

Control system

- Simatic S7-400 (5x)

- SIEMENS Master drives (98x)

- Communication via Ethernet, Profibus

- Disk cooling bed for steel plates

- Cooling of steel plates

- Plate transport from the cooling bed

- Double side rotary trimming shear section

- Double side rotary trimming shear knives

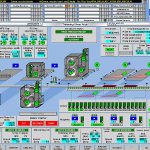

- HMI WinCC of the cooling section

- HMI of the trimming shear section

- HMI WinCC of the dividing section

- Stacking final plates (Piler machine) and plates expedition

- HMI WinCC of the stacking plates and their expedition